The Industrial Internet of Things has been an enabling factor for the innovative development of the manufacturing factory for years now. Although its application potential is known, it is important to continue studying and experimenting with new methodologies and new models that see it as the protagonist.

Zero-Defect Production

One of the many research goals is to find new IoT solutions that can make production zero defects, ensuring that every product or service provided meets established quality standards without any errors. You need:

- Standardize processes to ensure each step of production is performed consistently and best practices are followed;

- Prevent defects through careful planning;

- Don’t stop collecting information from the field to monitor progress and any changes.

New methodologies for the entire Value-Chain

Everything that happens within a production plant can be reproduced throughout the entire supply chain. The reference sector or the size of the companies involved is not important, each market player may be able to shape their own business model by accommodating new needs and introducing IoT solutions.

The Smart-Growth project

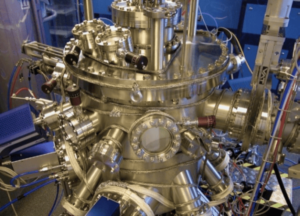

An example of the application of IoT solutions in a certainly niche sector is the Smart-Growth project (GA 01115130 | I3-2021-INV2a) which works in the context of the crystal growth process for applications in the photonic and laser fields. In this research project, of which Holonix is a partner, the approach we want to leverage is based precisely on the pillars of zero defects such as detection, prediction and prevention of faults and anomalies, with the objectives of increasing yield and efficiency of the process, reduce energy absorption, reduce waste and improve the quality of the crystals produced.

If you want to know more, read the article published on MacPlas!